If you’re seeking a surface-finishing method that’s efficient, repeatable, and gentle enough for complex geometries, vibratory finishing with vibratory bowls and media might just be your new secret weapon.

Vibratory finishing is a mass finishing process where workpieces are placed in a bowl or tub filled with finishing media and sometimes a compound. Vibration moves the parts and media against each other—effectively deburring, cleaning, polishing, or burnishing the surfaces depending on the type of media used. It works well for a wide range of materials and part complexities.

The vibratory bowl, often shaped with a ramp or built-in separation screen, automates the separation of parts and media, saving time and manual effort.

1) High-speed, high-throughput finishing

Vibratory bowls can finish large batches in one cycle—boosting production throughput and reducing per-part processing time.

Their action turns the media and parts into a fluidized bed, delivering consistent friction and fast, efficient finishing.

2) Consistent, Uniform Surface finishes

With controllable vibration settings (amplitude and frequency), even intricate shapes, internal cavities, and threaded features receive the same contact and finishing quality.

This consistency significantly reduces rework and rejects.

3) Reduced Manual Labor & Risk

Automated cycles cut down on hands-on finishing tasks—no more manual deburring. This increases operator safety, eliminates fatigue-related errors, and boosts efficiency.

4) Versatile and Gentle

Whether you’re working with steel, aluminum, brass, 3D-printed parts, or delicate alloys, vibratory finishing adapts.

Ceramic media handles hard metals; plastic or organic media (e.g., walnut shells) polish softer or fragile parts gently.

5) Cost-Effective Operations

These systems often deliver lower maintenance costs, energy-efficient operation, and quick batch cycles, compared to manual or blasting processes.

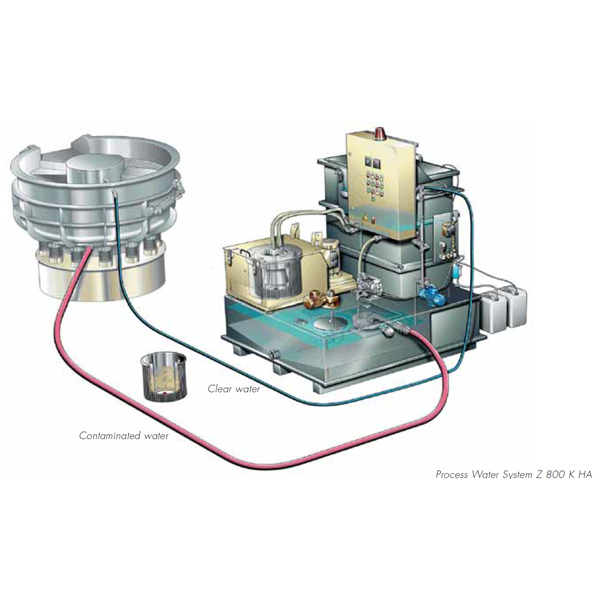

Wet vibratory processes can also reuse water, adding environmental and operational benefits.

6) Separation & Integration for Lean Manufacturing

Bowls with built-in separation screens allow easy part/media segregation—which simplifies integration with assembly lines and supports lean manufacturing principles.

-

Load parts, media, and compound into the bowl.

-

Activate vibration, creating a tumbling and shearing action.

-

Finish occurs as media abrades, polishes, or burnishes surfaces—depending on the media type and vibration setting.

-

Unload via the bowl’s ramp or screen, separating parts from media.

Depending on your machine—bowl, trough, or centrifugal finisher—you get different levels of efficiency and versatility.

-

Superior finish control via vibration, media, and compound selection

-

High consistency backed by controlled parameters and separation systems

-

Flexibility across industries—from aerospace to jewelry to automotive

-

Scalability—from small batches to high-volume runs

Moleroda offers vibratory machines, expert media selection, 5kg topping-up packs, and sampling support, ensuring the right solution at every scale.

Shop Vibratory Media & Equipment →

Q: What’s the difference between a vibratory bowl and a trough?

A: Bowls offer better part/media separation and higher throughput, while troughs are great for larger or longer parts in compact spaces.

Q: Is vibratory finishing suitable for delicate parts?

A: Absolutely—using low-frequency vibration with plastic or organic media delivers gentle, smooth finishing without damage.

Q: Is this more cost-effective than hand-finishing or blasting?

A: Yes—automation, efficiency, and reduced labour make vibratory finishing highly cost effective.

Conclusion

Vibratory finishing with bowls and media is a modern, efficient, and reliable method for delivering precision surface finishes with minimal effort—perfect for high-throughput, high-quality results.