Carbide Burr – H Shape (Flame) – on a 3mm Spindle

H-Shape Carbide Burr on a 3mm Spindle. Flame Shape.

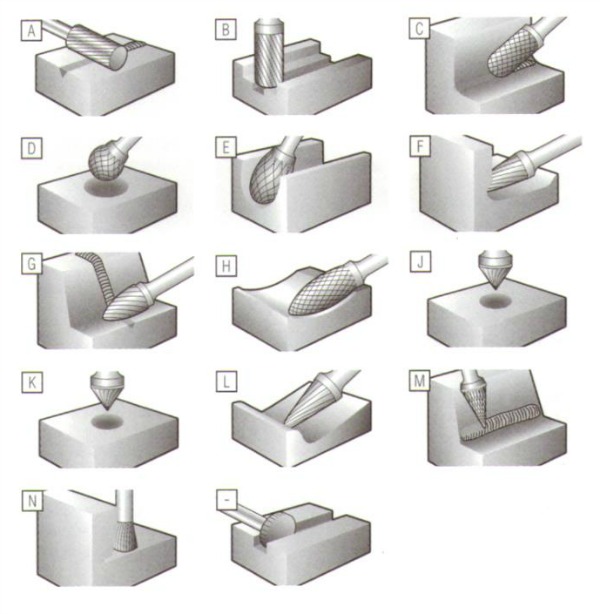

Carbide burrs are used for a wide range of stock removal and grinding operations including deburring, removal of sprues, blending welds and blending machine lines.

Our Carbide Burrs are of the SGSPRO range supplied by ATA Garryson, ensuring the highest quality.

H-Shaped Carbide Burrs have a pointed cone flame shape, ideal for deburring slots and holes.

- Plain Cut is for general purpose fluting. The second most popular cut.

- Double Cut/Cross Cut is the most popular fluting style. It is very efficient at stock removal, it creates a small chip resulting in a smoother finish. Use double cut for medium-light stock removal, deburring, finishing and cleaning.

- Diamond Cut is for use on heat treated and tough alloy steels where control is important. Creates a powder-like chip.

Applications for Carbide Burrs:

- Precision Deburring

- Polishing & Finishing

- Shaping, Moulding & Sculpting

- Smoothing, Chamfering & Bevelling Edges

- Detailing, Inscribing & Engraving

- Repair & Maintenance

Benefits of Using Carbide Burrs:

- High Quality & Durable

- Extremely Versatile & Cost-Effective

- Very Strong & Resilient

- Rapid material removal rate

- Exceptional precision & control for intricate design

- Capable of withstanding high temperatures with minimized heat generation

Best Features of Carbide Burrs:

- Carbide Burrs are exceptionally tough, durable and wear resistant

- Capable of withstanding high temperatures without significant loss of hardness or sharpness

- Efficient at material removal due to sharp cutting edges and aggressive cutting action

- Available in a wide variety of shapes, sizes and configurations

- Available on a 3mm/6mm Spindle or as a Carbide Burr Set

- Suitable for use with hand tools and CNC machining

- High quality SGSPRO range from ATA Garryson

Suitable Materials for Carbide Burrs:

- Metals – Steel, Aluminium, Brass, Copper, Cast Iron, Titanium

- Ceramics

- Composites – Kevlar, Fiberglass, Carbon Fiber

- Plastics

- Stone & Concrete

- Wood

Carbide Burrs recommended use with:

- Carbide Burrs can be used with a pendant motor, micromotor, air tool or hobby tool. – View our wide selection of machines here.

- Should be used at 70,000rpm for good, smooth results.

- They are a preferred choice in CNC machining for automatic deburring, cutting and finishing.

- Given potential tool variations, we advise confirming the spindle size needed for your particular tool.

Relevant Industries using Carbide Burrs:

- Automotive

- Aerospace

- Tool & Die Making

- Welding & Fabrication

- Glass & Ceramics

- Jewellery

- Metalworking & Woodworking

- Plastics & Composite materials

- Sculpture

For more information on deburring and polishing techniques visit our ‘how to’ pages.

For more videos of our products check out our You Tube channel.

![Carbide Burr - H Shape (Flame) - on a 3mm Spindle [1200x900]](https://moleroda.com/wp-content/uploads/2015/12/Carbide-Burr-H-Shape-3mm-1200x900-1.png)

![Carbide Burr - H Shape (Flame) - on a 3mm Spindle [1200x900]](https://moleroda.com/wp-content/uploads/2015/12/Carbide-Burr-H-Shape-3mm-1200x900-1-600x450.png)