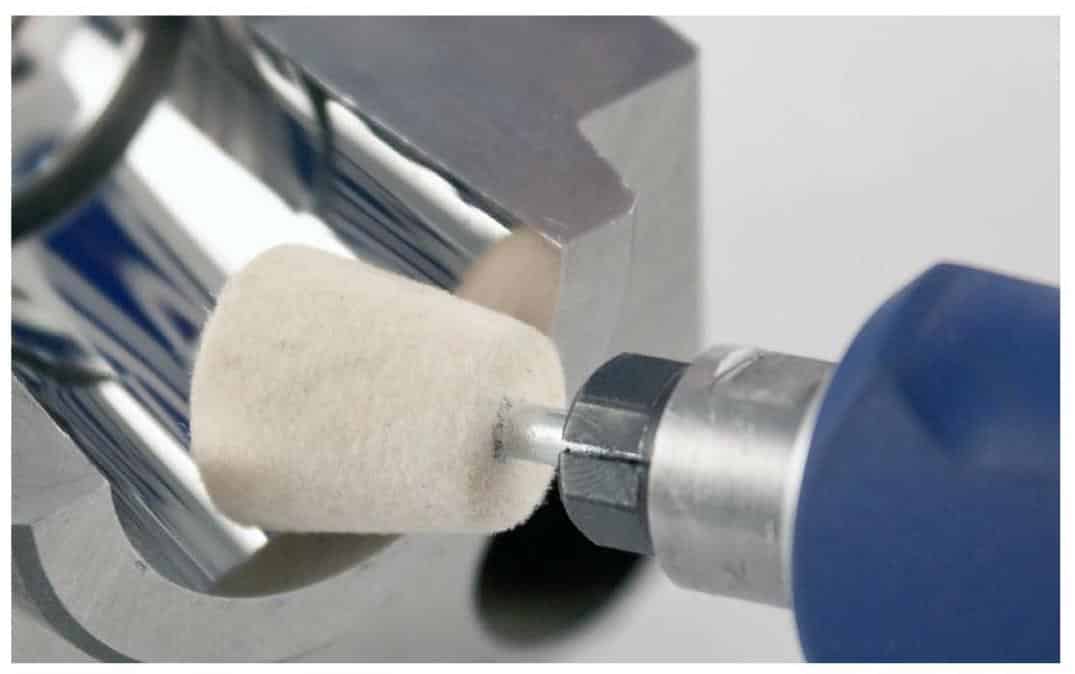

RODA Mounted Felt Bobs are professional-grade polishing tools designed for use with rotary equipment. Available on a 3mm or 6mm spindle, these felt bobs are ideal for polishing and finishing metal, glass, and plastic surfaces.

Why Choose RODA Felt?

With over 30 years of polishing expertise, RODA Felt is developed and manufactured in our UK factory in Wiltshire. Trusted by professionals across precision engineering, mould toolmaking, jewellery, dental, medical and aerospace industries, our felt polishing tools deliver high-performance finishing results with consistency.

Key Features of RODA Mounted Felt Bobs:

- Cost-effective and durable

-

Available in 3mm and 6mm spindle sizes (extended spindles available)

-

Made from high-density wool felt for optimum polishing performance

- Excellent compound carrier

-

Manufactured in our UK factory for reliable quality and fast delivery

- This means we can make felt bobs bespoke to your specific needs – just contact us.

-

Compatible with all standard polishing compounds

- Works exceptionally well with Diamond Compounds

- Works exceptionally well with Diamond Compounds

-

Suitable for metal, glass, plastics, and 3D printed parts

See why Felt is Ideal for Polishing Engineered Parts

Custom Options Available:

RODA Felts are made in our UK factory in Wiltshire. If you would like bespoke shapes – just get in touch if you require a different size, bespoke shape, different spindle or harder or softer density.

Felt Densities

-

Medium Density – Standard option, perfect for most polishing and finishing jobs (Supplied by default)

-

Soft, Hard & Hardened Density – Available upon request.

To better understand felt densities and how they can refine your process take a look at How to Choose the Right Felt Grade and Density for Polishing

Shapes & Sizes

Custom bespoke sizes are available upon request.

Shapes such as Cones, Wheels, and Points, Balls & Trapeze are also available.

Spindle Sizes

Standard: 3mm or 6mm

Extended or alternative spindle diameters are also available.

How to achieve the perfect finish with RODA Felt and Diamond Compound

1. Prior to polishing make sure you have gone up to 12000 or finer with Wet and Dry Sheets or RODA NyWheels for best results.

2. Insert your mounted RODA felt into a polishing machine – e.g. eneksa/micromotor.

3. Squeeze a pea sized amount of diamond compound onto your workpiece (when working with diamond compound usually start with a coarse grit like 20 microns and work up to a finer grit).

4. Then work the felt into the paste – a spray of lapping fluid will help to lubricate.

5. Keep the felt moving, wipe clean with solvent spray and a lint free polishing cloth.

6. Assess the finish and then move to a finer grade of diamond paste if required.

Applications:

RODA Mounted Felt Bobs are ideal for polishing:

-

Mould Tools & Dies

-

Precision Engineered Parts

-

Jewellery & Precious Metals

-

Dental & Medical Instruments

-

3D Printed Parts

-

Glass Components

-

Plastic Surfaces (consider Mounted Felt Flap Wheels for air-flow and cooling)

In this blog we break down How and Why You Should be Using Felt to Polish Metal

Compatible With:

-

Rotary tools (micromotor, pendant motor, flexible shaft machine, or standard drill) – Browse our full range of machines.

- Lea Compound, Diamond Compound, Menzerna, Rouge, Simichrome, Dialux, or any other compounds.

Prepare your surface thoroughly for best results – the final finish depends on the quality of pre-polish.

- for help with the pre-polish we recommend using Wet and Dry Sheets or RODA NyWheels.

Industries That Trust RODA Mounted Felt Bobs:

-

Precision Engineering

-

Toolmaking

-

Jewellery & Silversmithing

-

Medical & Dental

-

Aerospace

-

Automotive

-

Oil & Gas

-

Defence & Fabrication

Made in the UK | Fast Delivery | Custom Shapes Available

Browse our full RODA Range or call us for expert advice on the best mounted felt bobs for your application.