WHAT MAKES MICRO-MESH PADS UNIQUE?

Micro-Mesh pads feature a “soft touch” cushioned foam core with integrated “safety valve” action that allows abrasive crystals to recede under higher pressure rather than gouge the substrate, helping prevent deep stray scratches. The high-density foam also conforms to curves and contours without flat spots, making pads especially effective on complex shapes and small areas where sheets are less efficient.

Compared to rigid abrasives and standard paper sanding, Micro-Mesh pads deliver:

-

Controlled, ultra-fine finishing on tricky surfaces

-

Extended pad life — pads can be rinsed and reused

-

Reduced heat build-up during sanding

-

Comfortable hand control for detail work

For more on how Micro-Mesh pad technology works and how it compares to traditional abrasives, see our internal guide on 🔗Micro-Mesh Technology & Cushioned Abrasives

MICRO-MESH PADS: KEY FEATURES & BENEFITS

Enhance Surface Control

The foam core acts as a built-in safety mechanism — crystals recede under pressure rather than digging in — delivering consistent material removal and minimizing unwanted marks.

Superior Contour Conformity

Unlike flat abrasive sheets, soft touch pads follow curves and recesses easily, making them ideal for detailed, freehand work.

Extended Life & Reusability

Washable, double-sided pads offer significantly longer use compared to paper sanding, and the resilient bond maintains performance through multiple rinses.

Reduced Heat Buildup

The cushion core reduces friction heat — particularly valuable when working with heat-sensitive materials like acrylic and delicate varnish finishes.

TYPICAL APPLICATIONS

Micro-Mesh pads are widely used across finishing disciplines where controlled, high-clarity refinement matters:

-

Precision polishing of plastics, acrylics and polycarbonate

-

Small-area refinement on wood, composites and coatings

-

Metal finishing and decorative metalwork

-

Restoring clarity on clear surfaces and coatings

-

Instrument making, jewellery and detailed craft work

Discover detailed application techniques in our Micro-Mesh finishing guides and blog posts.

🔗How to Remove Scratches & Polish Acrylic with Micro-Mesh

🔗Smoothing & Finishing Wood with Micro-Mesh

🔗How Violin Makers use Micro-Mesh

🔗Polishing & Finishing Solid Surface Worktops with Micro-Mesh

HOW TO CHOOSE THE RIGHT MICRO-MESH PADS

Micro-Mesh pads are offered in a variety of sizes, types and set configurations to support different finishing workflows — from individual pad replacement to complete step-by-step abrasive progressions by type. Choose your options in three simple steps below.

Step 1 - Choose the Right Type

Micro-Mesh pads are available in the same three performance categories as other Micro-Mesh abrasives, helping you match the pad to your material and finish goal:

-

Regular – General finishing on plastics, soft woods and coatings.

-

MX (Metal Xtreme) – Durable option with tougher backing for metals and harder substrates.

-

AO (Aluminium Oxide) – Optimised for solid surface materials, aluminium and non-ferrous metals.

Each type spans a suitable range of grit grades and performance characteristics for controlled finishing.

For guidance on which type best suits your application, see our 🔗Micro-Mesh Grits & Grades Explained

Step 2 - Select Your Format

Individual Pads by Grade

Choose single Micro-Mesh pads in specific grit grades to complement your existing sequence or replenish used pads. Each pad is double-sided with the same grit and colour coding, making it easy to identify and use both sides to extend usable life.

Micro-Mesh pads use a unique grading system. Lower numbers (e.g., 60–400 MX) remove material faster, while higher numbers (e.g., 1500–12000) deliver progressively finer finishes.

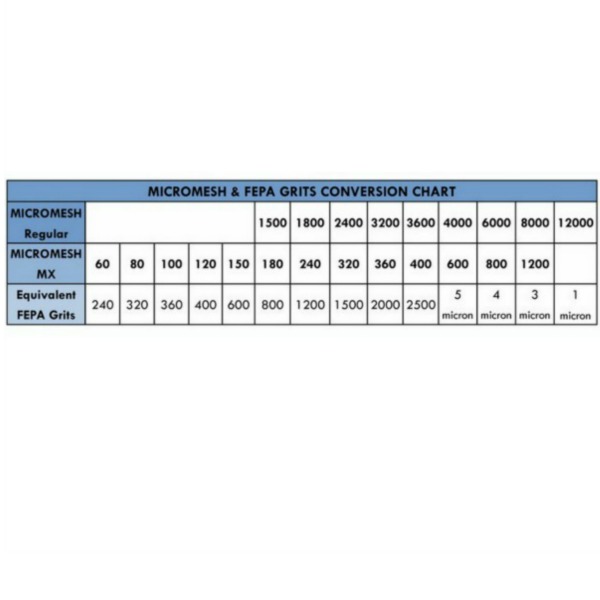

Here’s a rough overview of how the grading of Micro-Mesh ultra-fine abrasive pads matches up to standard abrasives:

| Micro-Mesh Grade | Approx. FEPA (P-Grit) Equivalent | Finishing Stage |

|---|---|---|

| 60MX – 120MX | P120 – P220 | Heavy stock removal (metal/hard surfaces) |

| 180MX – 400MX | P240 – P600 | Smoothing & pre-polish |

| 1500 – 2400 (Reg/AO) | P600 – P1200 | Initial polishing |

| 3200 – 6000 (Reg/AO) | P1500 – P3000 | High gloss refining |

| 8000 – 12000 (Reg/AO) | ~1 micron | Mirror / optical clarity polish |

For a full, detailed breakdown of Micro-Mesh pads grits & grades, see our 🔗Micro-Mesh conversion chart

For most projects:

-

Use coarser grits first to remove defects or tool marks.

-

Progress through finer grits for smoothing and polishing.

-

Finish with ultra-fine grades (8000–12000) for mirror-like results.

Pad Sets by Type & Grit Progression

Multi-grade assortments grouped by type and size so you can work through a logical finishing progression without guesswork. These sets typically include one pad per grade, double-sided so both sides are usable.

Whether you’re aiming for a satin finish or high-gloss polishing, these sets help remove the guesswork.

| Pad Set | Representative Grit Progression |

|---|---|

| Regular Pad Set (9-Grade) | 1500REG | 1800REG | 2400REG | 3200REG | 3600REG | 4000REG | 6000REG | 8000REG | 12000REG |

| MX Pad Set (13-Grade) | 60MX | 80MX | 100MX | 120MX | 150MX | 180MX | 240MX | 320MX | 360MX | 400MX | 600MX | 800MX | 1200MX |

| AO Pad Set (12-Grade) | 300AO | 600AO | 800AO | 1500AO | 1800AO | 2400AO | 3200AO | 3600AO | 4000AO | 6000AO | 8000AO | 12000AO |

These progressions follow a logical pattern to ensure each stage effectively removes the marks from the previous stage and prepares the surface for the next finer pad.

For help understanding the Micro-Mesh grading system and how to plan your progression, see our 🔗Grits & Grades Explained

Step 3 - Select Your Pad Size

-

2″ × 2″ Pads – Ideal for detailed areas, small curves and corner finishing where control and precision matter.

-

3″ × 4″ Pads – Larger surface area makes quicker coverage possible while retaining the soft-touch feel for consistent results.

LEARN MORE ABOUT MICRO-MESH

Explore our full library of resources for polishing, grade comparison, and project inspiration: