When it comes to achieving a flawless surface finish, grit size matters — but comparing Micro-Mesh to standard sandpaper can be confusing. Traditional abrasives use fixed mineral grains measured in FEPA (European) or CAMI (US) grit numbers, while Micro-Mesh uses its own grading system based on micron size and performance.

This guide explains exactly how Micro-Mesh grades relate to conventional abrasives, how to choose between the four Micro-Mesh types (Regular, MX, AO, and MXD), and which is best suited to your application.

Standard sandpapers are built around rigid grit bonded to paper. They cut aggressively and wear quickly, leaving deep scratches that must be polished out later.

Micro-Mesh, by contrast, is built for precision. Each abrasive crystal is embedded in a flexible latex layer on a durable cloth backing. This allows the crystals to move and cut evenly, producing a consistent scratch pattern that can be refined through progressively finer grades — right down to a mirror-smooth 1 micron finish (equivalent to FEPA 8000–12000).

In short:

-

Traditional sandpaper cuts fast but leaves scratches.

-

Micro-Mesh cuts cleanly, lasts longer, and creates a refined, uniform finish.

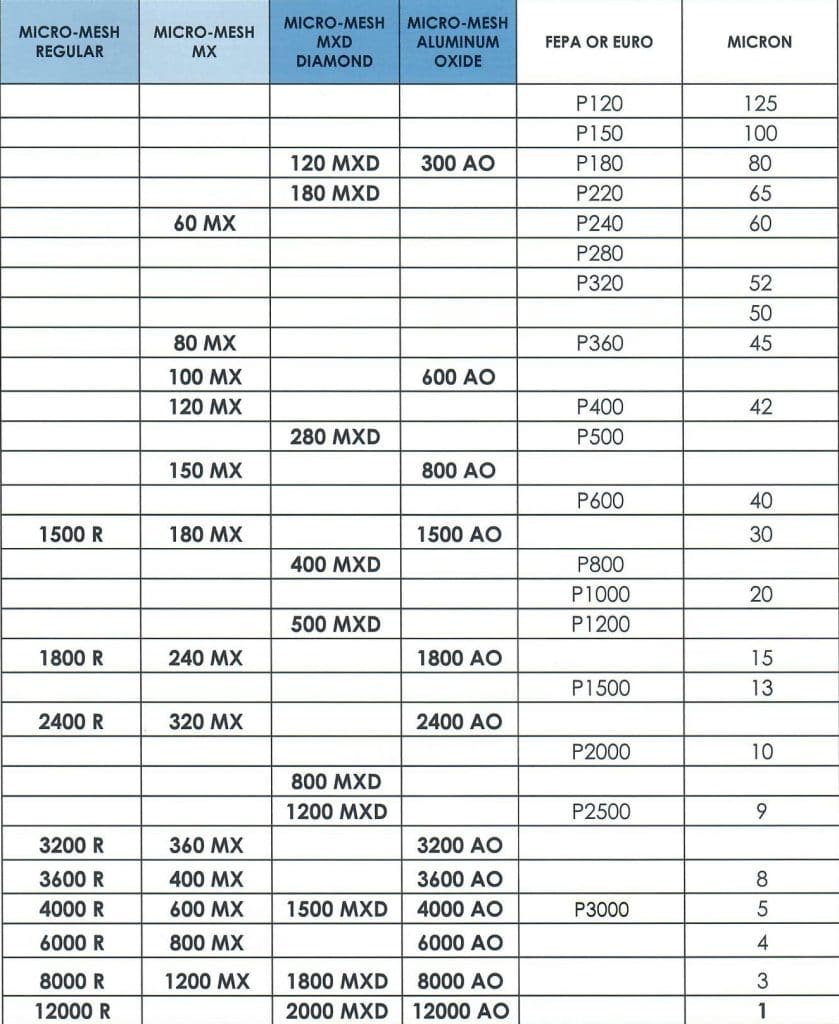

Micro-Mesh grades don’t directly match sandpaper grit numbers, but they do correspond roughly by performance. The table below shows approximate equivalents between Micro-Mesh, FEPA (European grit), and Micron size.

Tip: Move through grits progressively to avoid swirl marks or uneven surfaces.

Each Micro-Mesh variant uses the same core technology but is engineered for different materials and results. Here’s how they compare:

Micro-Mesh Regular (Silicon Carbide)

-

Grades: 1500 to 12000

-

Cut Type: Gentle, flexible

-

Best For: Plastics, paints, coatings, varnishes, soft metals, and wood.

-

Key Feature: The standard for Micro-Mesh performance. Produces a smooth, flat surface — ideal for transparent or glossy finishes.

Try: Micro-Mesh Regular Sheets or Hand Polishing Kits

Micro-Mesh MX (Silicon Carbide)

-

Grades: 60MX to 1200MX (approx. P240 to P8000 equivalent)

-

Cut Type: Faster, slightly firmer

-

Best For: Metals, hardwoods, and durable coatings.

-

Key Feature: Delivers a fast, clean cut on hard materials while maintaining a refined finish.

Ideal for: Engineering, toolmaking, precision metalwork, and hardwood polishing.

Micro-Mesh AO (Aluminium Oxide)

-

Grades: 300AO to 12000AO

-

Cut Type: Consistent and non-contaminating

-

Best For: Aluminium, composites, solid surface countertops (like Corian), and aircraft leading edges.

-

Key Feature: Leaves a bright, corrosion-free surface — perfect for non-ferrous metals.

Popular choice in: Aerospace and solid-surface finishing industries.

Micro-Mesh MXD (Diamond)

-

Grades: 120MXD to 2000MXD (80–1 micron)

-

Cut Type: Extremely fine yet durable

-

Best For: Ceramics, carbide, glass, stone, and hardened alloys.

-

Key Feature: Diamond abrasive for maximum life and minimal material removal — precise finishing for critical surfaces.

For ultra-hard materials, explore: Micro-Mesh Diamond Sheets & Discs

| Material | Recommended Type | Typical Grit Range | Finish Level |

|---|---|---|---|

| Soft woods & varnish | Regular | 2400–12000 | High gloss |

| Hardwoods & metals | MX | 60MX–1200MX | Fine to mirror |

| Aluminium & composites | AO | 300AO–12000AO | Bright polish |

| Ceramics & hard alloys | MXD | 120MXD–2000MXD | Precision finish |

Still unsure? Check out our guides on Smoothing and Finishing Wood with Micro-Mesh or How Violin Makers Use Micro-Mesh for real-world examples.

Understanding grit equivalence ensures you can integrate Micro-Mesh seamlessly into your workflow. Whether you’re replacing a traditional sandpaper system or refining a professional polishing process, Micro-Mesh offers the same (or finer) levels of finish with longer life and far greater control.

Moleroda Finishing Systems is a leading UK supplier of genuine Micro-Mesh abrasives, including sheets, pads, discs, belts, rolls and polishing kits. Whatever your surface — from wood to metal or acrylic — we’ll help you find the right product to achieve a perfect finish.