Deburring small parts

At Moleroda we specialise in precision finishing and deburring small parts. Working across industries such as automotive, aerospace, oil and gas and medical – we have helped remove burrs in the tightest of spaces on the smallest of parts. This includes washers, screws, nuts and bolts and parts as small as a 5 pence piece.

In this blog we detail the challenges of deburring small parts and some of the solutions we have devised and recommend in order to get rid of your burrs and create a smooth surface.

The Challenges

Deburring small parts presents unique challenges due to their size, complexity, and often delicate nature. Removing burrs from small parts requires precision and care to avoid damaging the components or affecting their dimensional tolerances. Here are several methods and considerations for deburring small parts effectively:

Challenges of Deburring Small Parts:

- Precision: Small parts often have tight tolerances, and even minor over-deburring can affect their functionality.

- Accessibility: Burrs on small parts may be located in difficult-to-reach areas, such as inside holes, threads, or fine features.

- Fragility: Small parts are often delicate and can be easily damaged by aggressive deburring techniques.

- Batch Processing: Handling and deburring many small parts efficiently can be challenging, especially when manual processes are involved.

Methods for Deburring Small Parts:

Manual Deburring

- Tools: Needle files, small deburring blades, flexi files

- Procedure:

- Use small, precision tools to manually remove burrs, being careful not to over-cut or damage the part.

- For intricate areas, use fine files or micro-abrasive tools.

- Inspect the part under magnification to ensure all burrs are removed.

- Best For: Low-volume production, intricate and delicate parts, or parts with very specific deburring requirements.

- Challenges: Time-consuming and dependent on operator skill, especially for intricate or numerous small parts.

Electronic Deburring

To add consistency and remove time deburring – a micromotor or ultrasonic tool is ideal. These units are used across engineering workshops in order to ensure precision and control. By using deburring consumables with a micromotor or ultrasonic you can change the speed, change the rotation and ensure you can get into small parts.

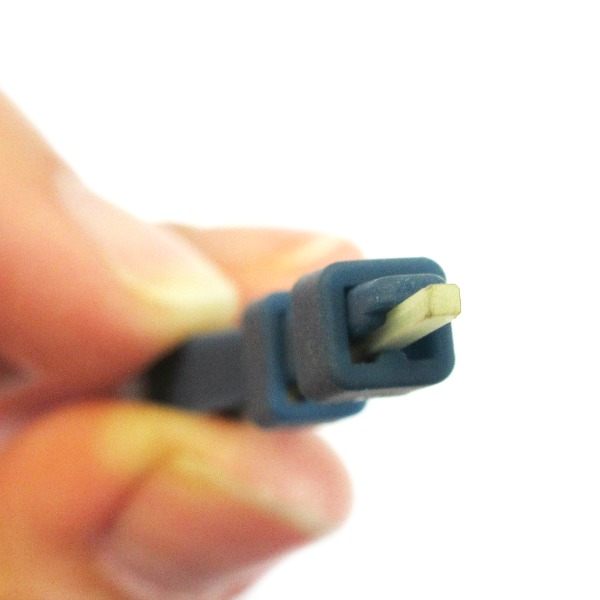

- Tools – Eneska or Oz black Micromotor or Eneska Ultrasonic with mounted consumables such as micropoints or elastic points.

- Procedure:

- Use electronic units which can automize using small, mounted precision tools to manually remove burrs, being careful not to over-cut or damage the part.

- For intricate areas, use ultrasonic stones .

- Inspect the part under magnification to ensure all burrs are removed.

- Best For: ultimate precision, intricate and delicate parts, or parts with very specific requirements.

Micromotor Systems

Moleroda OZ Black Micromotor System with Handpiece and Foot Pedal

Abrasive Hand Tools

Abrasive Hand Tools

Diamond Points

Vibratory, Tumbling or Magnetic Finishing

- Tools: Vibratory finishing machine or magnetics spinner, abrasive media (ceramic, plastic, or steel or pins), and compound.

- Procedure:

- Load the small parts into the machine along with the appropriate media.

- Run the machine for the required time, which can vary depending on the part and media used.

- After processing, parts are usually rinsed and inspected.

- Best For: Batch processing of large quantities of small parts, especially if they have simple geometries.

- Challenges: Uniformity can vary, and media selection is critical to avoid damaging delicate parts.

Tips for Effective Deburring of Small Parts:

- Magnification: Use magnifying tools or microscopes to inspect and deburr small parts with precision.

- Batch Processing: When possible, choose methods like vibratory finishing or tumbling to deburr multiple small parts simultaneously.

- Material Considerations: Tailor the method to the material of the small parts—softer materials may require gentler methods, while harder materials may need more aggressive techniques.

- Testing and Iteration: For high-precision or high-value parts, test different methods on sample parts to find the best approach.

- Surface Finish Goals: Consider how the process will affect the final surface finish and, if necessary, follow up with polishing or fine finishing steps.

More Information

For more information on deburring give us a call – we have experts here who have been polishing and deburring for years!

And take a look at our You Tube page for videos of us hard at work finishing!