Whether you’re deburring, polishing, or preparing components for plating, choosing the right vibratory finishing media is critical to achieving the perfect finish. The right media will:

-

Improve efficiency

-

Deliver consistent results

-

Prevent part damage

-

Reduce costs over time

Shop Vibratory Finishing Media →

At Moleroda, we’ve helped thousands of engineers find the right solution. This guide will walk you through everything you need to consider:

Your finishing goal determines the media type, shape, and grade you need:

| Goal | Recommended Media | Notes |

|---|---|---|

| Deburring | Plastic or Ceramic (Angular Shapes) | Angular media reaches edges and holes; rounded gives softer action for light deburring. |

| Polishing | Porcelain Pins or Walnut Shells | For a bright, mirror-like finish. |

| Surface Texture Control | Ceramic (Duller Finish) / Plastic (Brighter Finish) | Choose based on desired aesthetic or functional finish. |

| Cleaning Laser/Waterjet Cuts | Aggressive Ceramic Media | Removes oxide and sharp edges efficiently. |

| Removing Cast “Orange Peel” | Aggressive Ceramic Media | Smooths rough cast surfaces quickly. |

Different materials respond differently to vibratory finishing:

| Material | Recommended Media | Reason |

|---|---|---|

| Stainless Steel | Ceramic | Handles hard metals effectively |

| Aluminium | Plastic | Gentler action prevents damage |

| Brass | Plastic | Protects softer metals |

| Cast Iron | Ceramic | Aggressive cutting action |

| Plastics | Plastic | Softer action; depends on part |

| Part Type | Recommended Media | Why |

|---|---|---|

| Very Small Parts | Small Ceramic Media | Reaches fine details |

| Intricate/Delicate Parts | Plastic Media or Porcelain Pins | Softer action avoids damage |

| Medium, Simple Parts | Larger Media | Faster processing, more economical |

| Highly Machined Components | Plastic or Ceramic (carefully sized) | Avoids media packing in tight areas |

| External Threads | Non-aggressive Plastic | Light deburring without damage |

The type of vibratory finishing machine also influences media selection:

Small Bench-Top Bowls

| Recommended Media Approach | Notes | |

|---|---|---|

| More aggressive media | Speeds up long processing times |

Vibratory Mini Bowls (30, 60, 120)

| Recommended Media Approach | Notes | |

|---|---|---|

| Less aggressive media | Ideal for polishing and delicate parts |

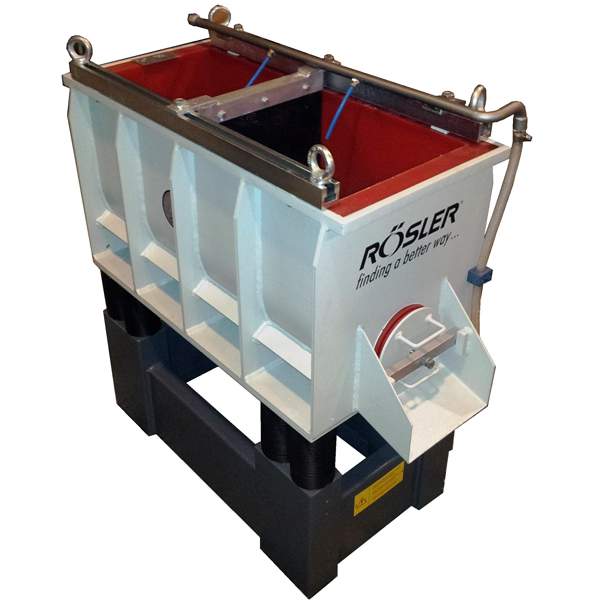

Vibratory Trough Machines

| Recommended Media Approach | Notes | |

|---|---|---|

| Plastic or Ceramic | Good for general deburring, less so for polishing |

High-Energy Centrifugal Machines

| Recommended Media Approach | Notes | |

|---|---|---|

| Any media type | Faster processing, even with softer media |

Machines, Tools & Equipment

Centrifugal (Disc) Finishing Machines for polishing and deburring

We’re proud suppliers of Rosler, global leaders in vibratory finishing media:

-

Over 60 years of expertise

-

8,000+ media types in stock

-

Used by aerospace and automotive giants worldwide

-

Manufactured in Germany under strict quality standards

-

Consistent wear patterns for repeatable, reliable results

Rosler media ensures efficiency, quality, and predictable performance every time you top up your machine.

At Moleroda, we supply:

-

Ceramic Media: For deburring steel and stainless steel

-

Plastic Media: For aluminium, brass, and softer metals

-

Polishing Media: Walnut shells, porcelain pins for bright finishes

Take a look here for a the full range of available media sizes and grades

We also offer free process trials. Send us your components—we’ll test them and recommend the best media for your material, machine, and budget.

Conclusion

Choosing the right vibratory finishing media involves considering:

-

Your finishing goal

-

Material type

-

Part size and geometry

-

Machine type

At Moleroda, we make it easy to find the perfect ceramic, plastic, or polishing media—available in convenient 5 kg topping-up packs for flexibility and cost savings.

I like that you provided some insights on what kind of finishing media to use such as determining first what type of material you’re working on. I didn’t realize that there is actually quite a variety such as aluminum, brass, and metal. Nevertheless, it’s good to know that there are certain websites on the internet where you can shop around to purchase the best vibratory finishing media according to your needs. If I were to purchase my own burnishing media, I would make sure to keep this in mind. Thanks.