EDM Polishing Stones are hard aluminium oxide stones engineered for polishing and finishing EDM-machined surfaces. These durable stones break down slowly, retain their shape, and deliver excellent results on hard tool steels.

Perfect for removing EDM spark-eroded scale, they are widely used in toolmaking, mould polishing, die finishing, and precision engineering.

Key Features

-

Specially formulated for EDM machining cleanup

Removes hard, stubborn EDM scale quickly without glazing. -

Long-lasting, hard aluminium oxide structure

Breaks down slowly while maintaining shape for consistent results. -

Ideal for tool steels and hardened materials

Suitable for most polishing and toolroom applications. -

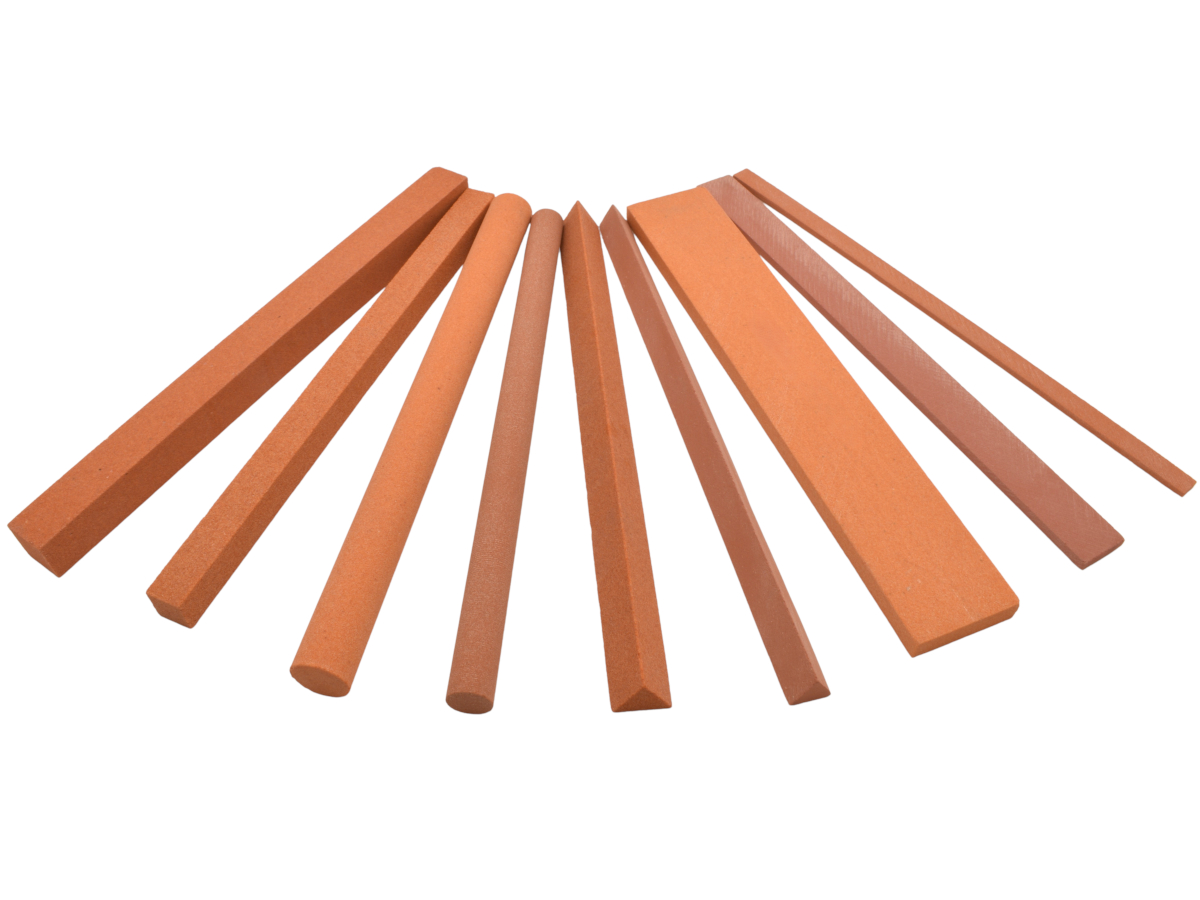

Available in 5 shapes

Flat, Square, Round, Half-Round and Triangle. -

6 grit options: 120, 180, 220, 320, 400, 600

From aggressive stock removal to fine pre-polishing. -

Use by hand or with a power tool

Compatible with our Hand Held Stone Holders or Machine Stone Holders -

Recommended with Lapping Fluid

For cleaner cutting, cooling and reduced stone loading

What Are EDM Polishing Stones?

EDM stones are specialist abrasive stones designed for the polishing and finishing of metal surfaces after Electrical Discharge Machining (EDM). The EDM process leaves a hardened, textured, and often brittle scale layer that can compromise performance and precision.

Our EDM series stones are engineered to remove this tough surface uniformly, allowing the operator to quickly refine and smooth the material in preparation for finishing and polishing. They are particularly effective for die repair, mould polishing, tool steel finishing, and detailed handwork.

Applications

-

Removal of spark-eroded scale

-

Tool and die polishing

-

Mould cavity finishing

-

Precision deburring

-

Detail polishing in aerospace, medical and automotive components

-

Hard tool steel and high-chromium steels

Available Variations

All stones are 6″ long with the exception of 1/8″ and 5/32″ stones being 4″ long.

If your desired size/grit isn’t in stock, please contact us to discuss pricing.

Stone Shape

Flat / Rectangular EDM Stones

| Size | 120 | 180 | 220 | 320 | 400 | 600 |

| 1/4″ x 1/16″ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 1/4″ x 1/8″ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 1/2″ x 1/16″ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 1/2″ x 1/8″ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 1/2″ x 1/4″ | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 3/4″ x 1/8″ | ✆ | ✆ | ✆ | ✆ | ✆ | ✆ |

| 3/4″ x 1/4″ | ✆ | ✆ | ✆ | ✆ | ✆ | ✆ |

| 3/4″ x 1/2″ | ✆ | ✆ | ✆ | ✆ | ✆ | ✆ |

| 1″ x 1/8″ | ✆ | ✅ | ✆ | ✅ | ✆ | ✅ |

| 1″ x 1/4″ | ✅ | ✅ | ✅ | ✅ | ✆ | ✆ |

| 1″ x 1/2″ | ✅ | ✅ | ✅ | ✅ | ✆ | ✆ |

Square EDM Stones

| Size | 120 | 180 | 220 | 320 | 400 | 600 |

| 1/8″ Sq. | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 5/32″ Sq. | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 1/4″ Sq. | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 3/8″ Sq. | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 1/2″ Sq. | ✅ | ✅ | ✅ | ✅ | ✅ | ✆ |

| 1″ Sq. | ✅ | ✆ | ✆ | ✆ | ✆ | ✆ |

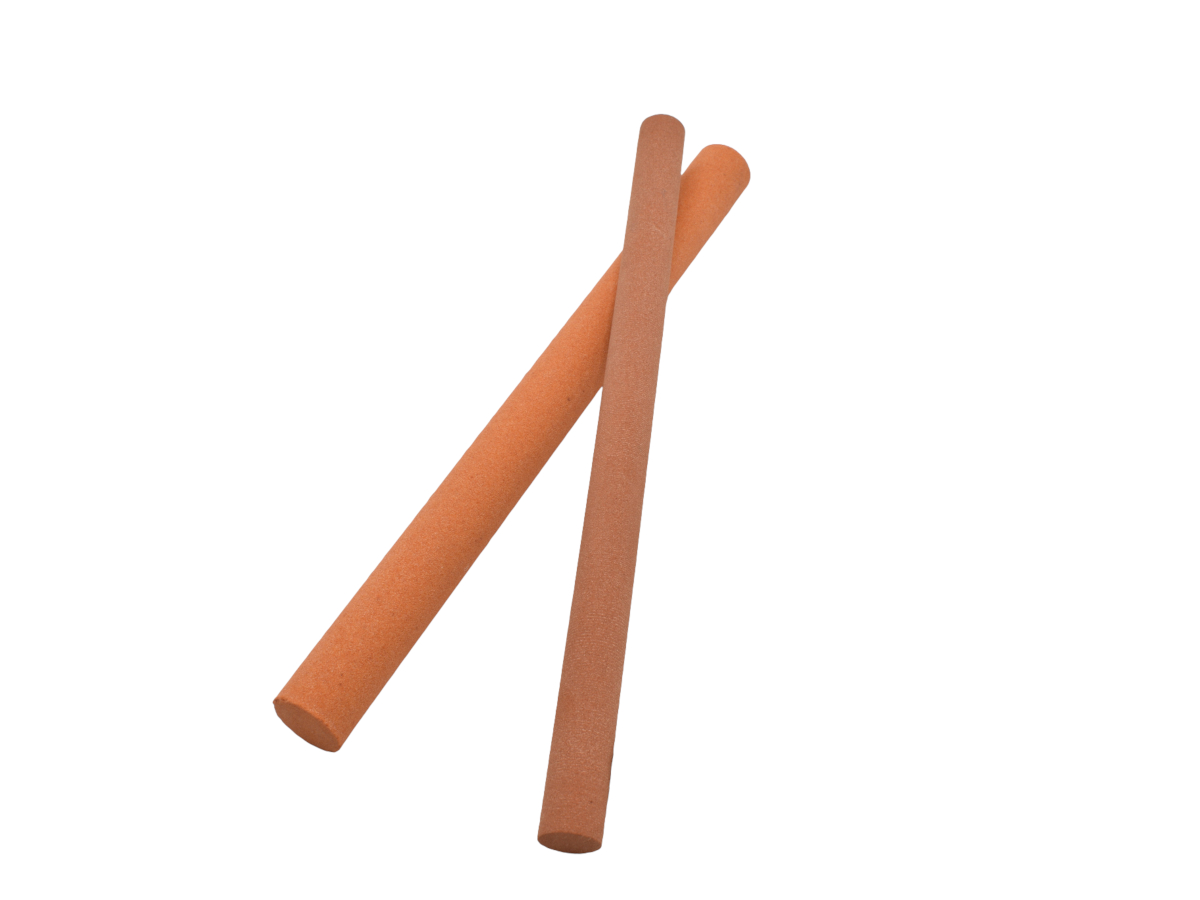

Round EDM Stones

| Size | 120 | 180 | 220 | 320 | 400 | 600 |

| 5/32″ Rd. | ✅ | ✅ | ✆ | ✅ | ✆ | ✆ |

| 1/4″ Rd. | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 3/8″ Rd. | ✅ | ✅ | ✅ | ✅ | ✆ | ✆ |

| 1/2″ Rd. | ✆ | ✅ | ✆ | ✅ | ✅ | ✆ |

Half-Round EDM Stones

| Size | 120 | 180 | 220 | 320 | 400 | 600 |

| 3/8″ HR. | ✆ | ✆ | ✆ | ✅ | ✆ | ✆ |

| 1/2″ HR. | ✆ | ✆ | ✆ | ✅ | ✆ | ✆ |

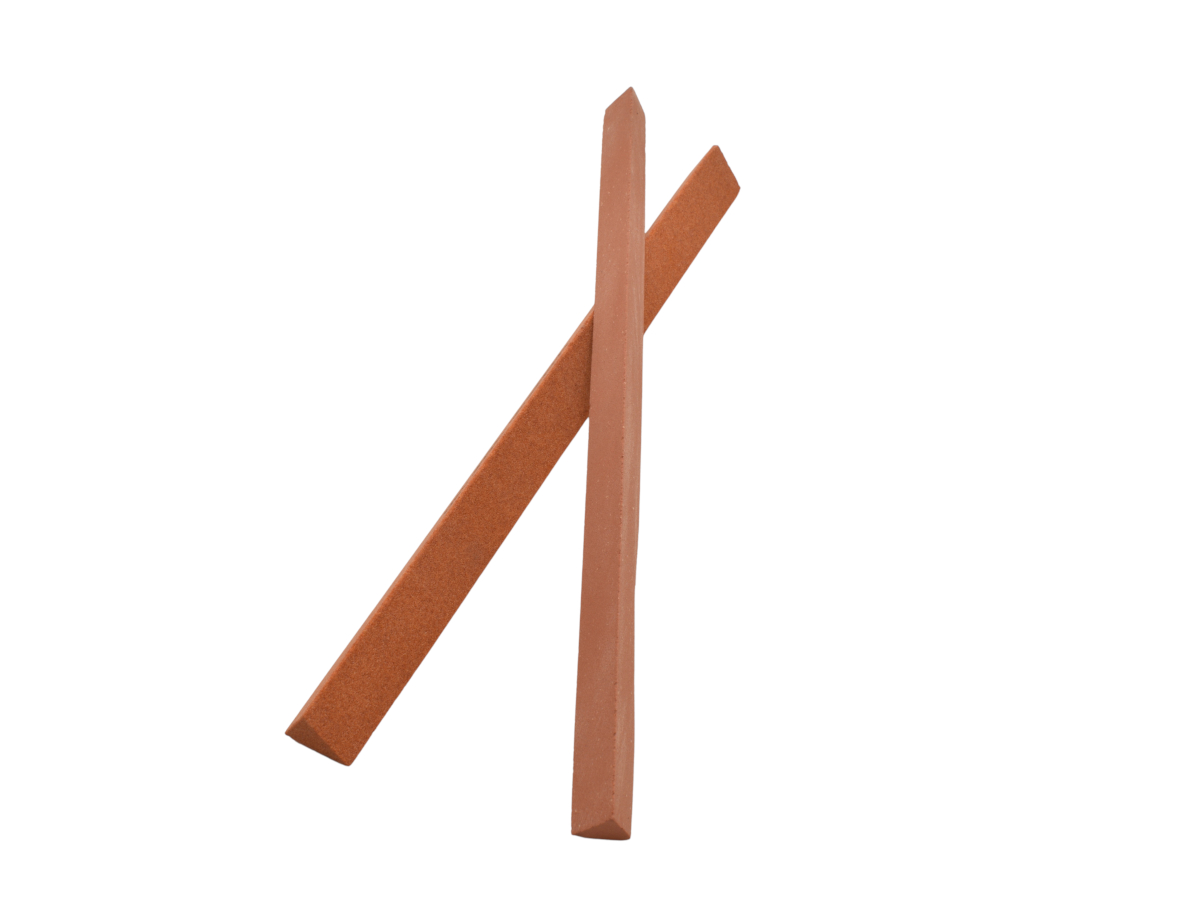

Triangular EDM Stones

| Size | 120 | 180 | 220 | 320 | 400 | 600 |

| 1/4″ Tri. | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| 3/8″ Tri. | ✅ | ✅ | ✅ | ✆ | ✅ | ✅ |

| 1/2″ Tri. | ✆ | ✅ | ✅ | ✅ | ✅ | ✆ |

| 1″ Tri. | ✆ | ✆ | ✆ | ✆ | ✆ | ✆ |

Why Choose Moleroda?

Our in-house finishing experts have decades of experience in polishing and tool finishing. If you’re unsure which EDM stone shape, size or grit you need, speak to our team and we’ll guide you to the right setup.

Visit our YouTube channel to see polishing demonstrations and application tips.

What are EDM polishing stones used for?

EDM polishing stones are specialized abrasive tools used to remove rough surfaces, spark erosion, and scale left after Electrical Discharge Machining (EDM). They create a smooth, polished finish on hard tool steels, moulds, dies, and precision components.

What shapes and sizes are available?

Our EDM stones come in five shapes: Flat, Square, Round, Half-Round, and Triangular. Each shape is available in multiple sizes and six grit options: 120, 180, 220, 320, 400, and 600. Most stones are 6” long, except some small stones (1/8” & 5/32”) which are 4” long.

How should I use EDM stones?

EDM stones can be used by hand (with a stone holder) for precision work or with a power tool using a machine stone holder. For best results, use with a lapping fluid to lubricate the stone, reduce loading, and improve cutting efficiency.

What materials can EDM stones polish?

They are ideal for hard tool steels, stainless steels, and other hardened metals. They are excellent for dies, moulds, and components requiring a high-quality polished finish.

How long do EDM stones last?

Our hard aluminium oxide stones are designed to break down slowly and retain their shape, providing consistent results over multiple uses. Proper use with a stone holder and lapping fluid will extend their life.

How do I choose the right grit?

-

120–220 grit – aggressive removal of EDM scale and rough material.

-

320–600 grit – fine polishing and surface finishing.